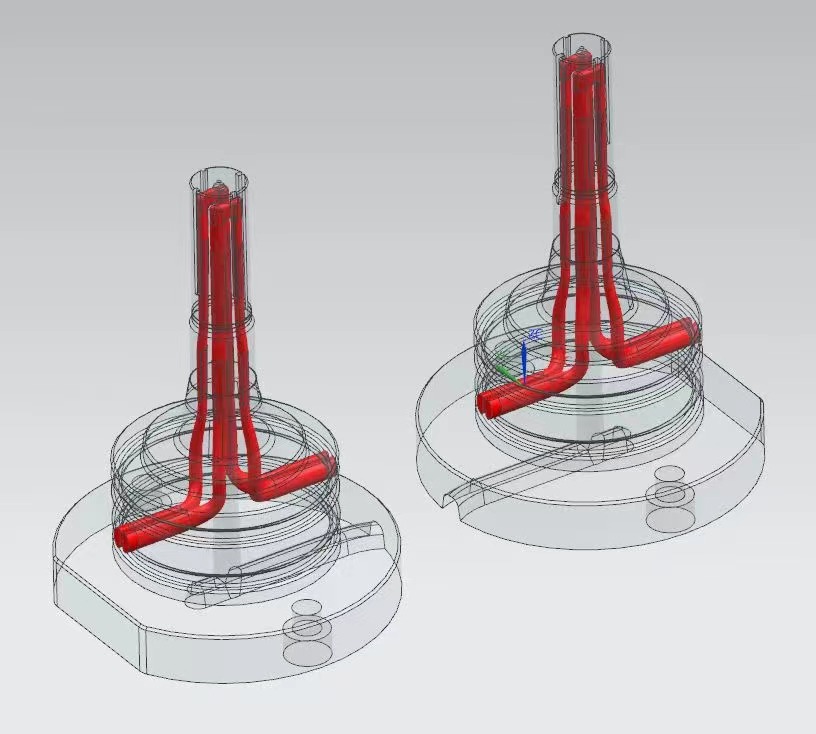

The conformal water channel mold made by metal 3D printing can evenly distribute the water channels along with the shape of the product, thereby further reducing the molding cycle and increasing the added value of the final product.

As metal 3D printers and material development continues to improve, printing accuracy continues to improve and printing prices have dropped to an acceptable range, 3D printed conformal waterway workpieces have been recognized by more and more users.

Metal 3D printing has been widely used in packaging, automobiles, electronic 3C, medical, home appliances and other industries, such as: game controller molds and charger shell molds in the electronic 3C industry, PEGT hot runner inverted pile molds in the packaging industry, fuse boxes, Automotive connectors etc.

Welcome to send your inquiries to info@lingel-pro.com. Our engineering team will help from design to printing.