Medical catheters are an important part in the modern medical equipment, which are widely used in various medical procedures, including diagnosis, treatment, and monitoring. In order to meet different medical needs, the processing of medical catheters requires high-precision and high-quality production processes. Lingel Pro provides the following medical catheter processing services.

1. Extrusion molding

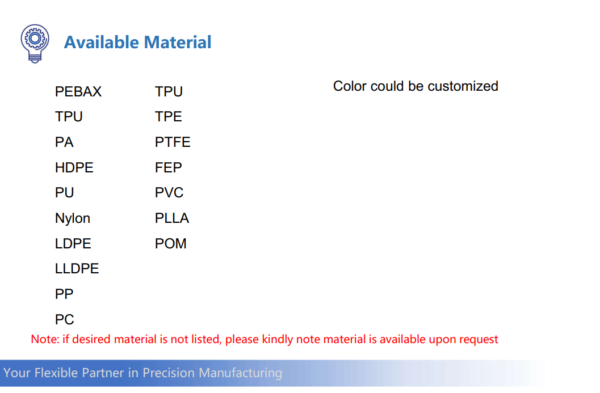

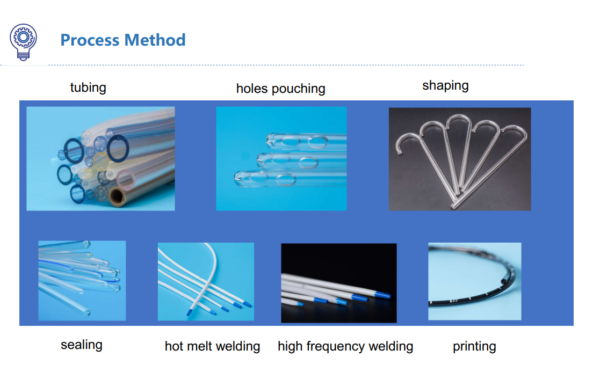

Extrusion molding is one of the most common methods of manufacturing medical catheters. We use advanced extrusion equipment and technology to produce conduits of various materials (such as PVC, PU, silicone, etc.) and specifications. Our extrusion process ensures catheters with excellent physical properties and biocompatibility for a variety of medical applications.

2. Laser cutting and holes punching

Laser cutting and holes punching techniques are used to precision machine catheters to meet specific medical needs. Our laser equipment is capable of high-precision cutting and punching, ensuring that the size and shape of the catheter fully meets the design requirements, while maintaining a smooth edge and reducing damage to patient tissue.

3. Thermoforming

Thermoforming technology is used to manufacture medical catheters of complex shapes. Through heating and mold forming, we are able to produce catheter shapes in specific medical needs, such as curved, tapered, etc. Our thermoforming process ensures that the catheters maintains the material’s physical properties and stability during deformation.

4. Ultrasonic welding

Ultrasonic welding is an efficient method of joining pipes and is suitable for a variety of plastic materials. By using ultrasonic vibration to rapidly melt and fuse the contact surfaces, we are able to achieve a seamless connection of the catheter, ensuring its strength and sealing, which is suitable for high-pressure and high-flow medical environments.

5. Surface treatment and coating

To enhance the performance of catheters, we have a variety of surface treatments and coating services. These include but not limited tto antimicrobial coatings, lubricating coatings, and hydrophobic or hydrophilic treatments. These coatings and treatments not only improve the biocompatibility of the catheter, but also reduce resistance and prevent bacterial infection, improving safety and comfort.

6. Customized design and development

Our experienced R&D engineers can provide customized design and development services according to medical catheters’ specific needs. From conceptual design to prototyping to volume production, we work closely with you to ensure that each catheter meets the stringent requirements of its specific application.

7. Quality control and testing

From raw material procurement to finished product delivery, every link has undergone strict quality testing. We use advanced testing equipment and methods to ensure that each catheter meets our customers’ specific requirements.

As a professional medical processing service provider, Lingel Pro is committed to providing customers with high-quality, reliable and safe medical catheter products. Whether it is standardized production or customized needs, we can provide optimal solutions to help the development of the medical industry and improve patients’ treatment effects and quality of life. If you have any medical catheter processing needs, please feel free to contact us and we will serve you wholeheartedly.