In the world of automotive casting applications, precision, reliability, and cost efficiency are paramount factors. Automotive components such as cylinder heads, transmission housings, and EV motor parts normally require exceptional durability and high-performance standards. In our actual delivered cases, we found outpoint cooling and composite surface treatments have become increasingly important. Together, these techniques not only improve the quality of castings, but also extend tool life and reduce defects—key factors for modern automotive manufacturing.

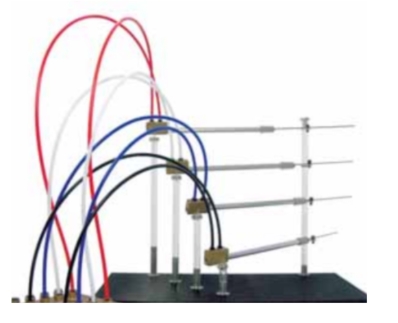

What is Point Cooling and Composite Surface Treatment?

Point cooling involves the precise control of cooling channels embedded into the mold core, ensuring even and rapid cooling of the molten metal. Meanwhile, composite surface treatments enhance the hardness, wear resistance, and overall durability of the mold cores. When combined, these two methods ensure the automotive casting components being produced with the highest quality standards and long-term performance in mind.

Benefits of Point Cooling in Automotive Casting

- Extended Tool Life

Tool longevity is crucial in high-volume automotive casting. Without proper cooling, mold cores suffer from rapid wear and require frequent maintenance. However, by utilizing point cooling, automotive casting manufacturers can significantly extend the service life of the molds. As a result, they reduce the need for frequent mold replacement and maintenance costs, which is essential for cost-effective production in the automotive industry and remain competitiveness. - Reduced Shrinkage Porosity and Gas Pores

One of the other major issues in automotive casting is the formation of shrinkage porosity and gas pores, which can weaken the structural integrity of the final casting product. Fortunately, point cooling helps minimize porosity, ensuring better consistency and improved performance of critical automotive components. - Improved Leak Tightness

Leak-tightness is an unacceptable factor in automotive components, especially in high-pressure systems like engines and transmissions. When point cooling is applied in molding, it leads to uniform solidification of the final casting metal parts and minimizes leakage. Consequently, this enhances the reliability and performance of automotive parts.

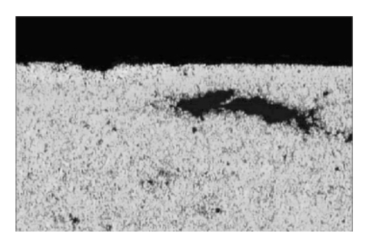

Without point cooling, final casting parts with shrinkage holes

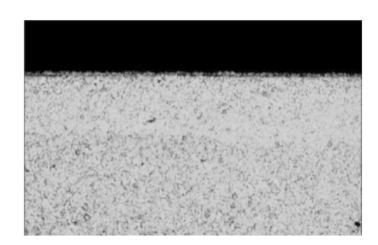

With point cooling, the shrinkage around it is significantly reduced.

Key Results from Using Point Cooling and Composite Surface Treatments

- Enhanced Core Durability: Test results show that nitrided cores without point cooling wear out quickly after about 5,000 shots. If with point cooling wear performance is better, whereas those with point cooling and composite surface treatment remain intact for up to 10,000 shots, significantly improving productivity.

- Better Porosity Control: Point cooling results in fewer shrinkage defects and gas pores. Therefore, automotive casting components benefit from a more uniform structure, which reduces the need for post-production inspections and reworks.

- 64% Reduction in Leak Rates: Automotive casting components made with point-cooled molds exhibit a 64% reduction in leak rates, which means they consistently meet strict performance standards.

① Nitrided core after 5000 cycles with no spot cooling.

② Nitrided core after 5000 cycles with spot cooling.

③ Composite surface treated core after 10000 cycles with spot cooling.

Why Automotive Manufacturers Should Adopt Point Cooling and Surface Treatment

- Cost Savings: By extending the life of mold cores and reducing the frequency of repairs, automotive casting part manufacturers can save significantly on maintenance costs. At the same time, they improve overall production efficiency.

- Increased Production Efficiency: Consistent tool life and fewer defects result in faster production cycles and less downtime. As a result, this leads to higher throughput for automotive casting manufacturers.

- Superior Quality for Safety-Critical Parts: Automotive casting components like brake systems, engine blocks, and transmission housing parts require superior durability and strength. With the combined use of point cooling and composite surface treatments, automotive casting manufacturers can guarantee that parts remain free from defects, comply with safety standards, and deliver long-term performance.

Condition of the hardened layer without cooling

Optimized condition of the hardened layer with cooling

Conclusion: Point Cooling and Surface Treatments for Automotive Excellence

For the automotive industry, where every casting must meet stringent quality and safety standards, the combination of point cooling and composite surface treatments offers an unbeatable advantage compared with only nitrided parts. Not only does these methods improve tool life, but they also ensure higher casting quality, reduces defects, and enhances leak tightness—all of which are essential for producing high-performance automotive casting components.

In conclusion, by utilizing these advanced techniques, automotive manufacturers can achieve greater operational efficiency, cost savings, and enhanced product reliability.

Unlock the full potential of your die casting process! Contact us now to see how our advanced automotive cooling solutions have helped companies like yours improve efficiency, reduce costs, and stay ahead of the competition. Let’s work together to find the perfect solution for you.