Besides metal 3D printing service, Lingel-Pro also provides conformal cooling design service!

Why?

When checking customers’ cases, we find out that customers have really brilliant ideas in achieving their ideas with 3d printing, while they do not have much expertise in improving the conformal cooling successful rate. Reasons are several and conformal cooling design is one among thoses.

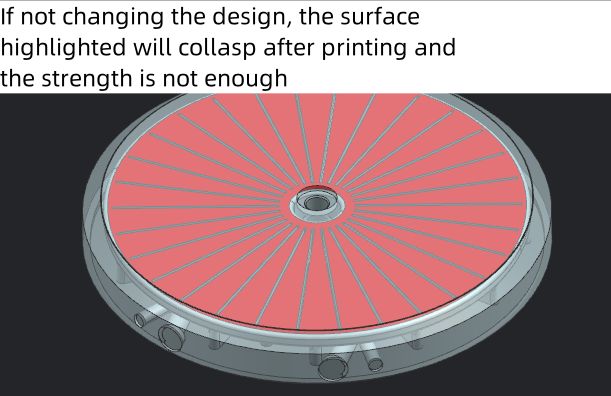

As we could see from the left picture, the original design done by customer is not the best design option for metal 3D printed injection molding.

If we print it without any modification, then the surface will collasp afterwards, and the strength is not enough too.

After checking the final injection material, our engineer suggests the updated conformal design as the left picture shows.

In this design, it will give enough surface support also the four water outputs are allocated in the side so it won’t affect the surface.

What’s more, we suggest to print the injection molding with graft printing, which means first made the straight bottom waterways base with traditional CNC methods, then printed the curved waterways with 3D printing.

In this way, both the cost and outcome is achieved without any compensation!

We welcome any inquiries about your ideas in injection molding made in 3D printing ways. Fell free to reach us via info@lingel-pro.com!