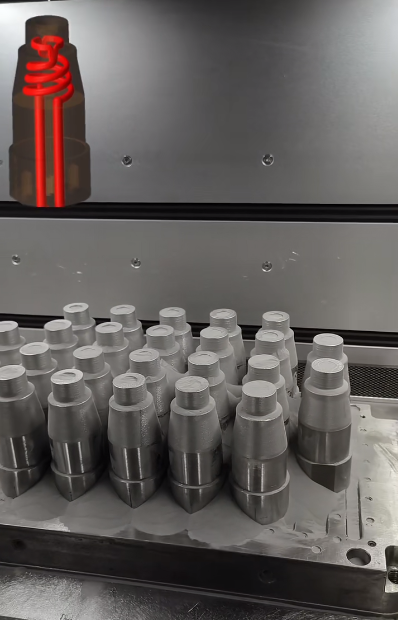

This is a freshly printed multi-cavity waterway workpiece. We could see the internal waterway design in the upper left picture and it is more complex then traditionally produced ones. It is difficult to achieve such a complex waterway using traditional processing methods like CNC. If we print directly the entire waterway, the cost will increase accordingly. In order to save costs, we adopt the grafting printing method that we have maturely applied, that is, first process the straight water channel at the base, and then use 3D printing to process the integrated conformal water channel on the top.

In this way, grafting printing can not only reduce the cost of 3D printing, but also shorten the subsequent injection molding cycle by more than 20%. We have applied the state-of-art technique to medical, 3C, home appliances and other industries.

Welcome to give us the injection molding problems in your industry, and we will provide you with a conformal waterway design plan and realize it with metal 3D printing!